practical use of impact test|types of impact tests : supplier Impact Tests with High-Speed Testing Machines. The HTM high-speed testing machine is of universal use in plastics testing. It covers a very high test speed and large force range, and . 19 de jul. de 2023 · Uma das primeiras opções que vemos assim que pegamos no cartão do Placard é a chamada aposta simples. Como o nome indica, estas apostas são bastante básicas: o sistema permite um .

{plog:ftitle_list}

WEBPrezentare generală a subiectelor: Cele mai bune cazinouri Germania Criteriu recenzie Siguranță cazino Cazino software Catalog jocuri Jocuri live Top bonusuri Cele mai bune metode de plată Concluzie FAQ Cele mai bune cazinouri online din Germania – topul site-urilor 2024 pentru jucătorii români. Descoperă recenzii despre cele mai bune cazinouri .

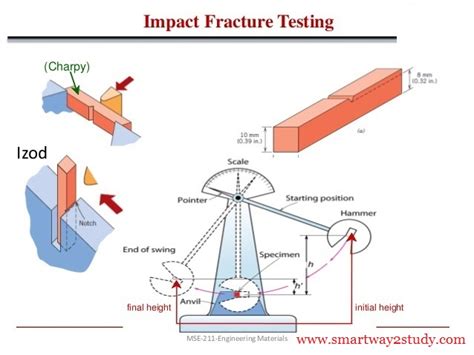

An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact . The Tinius Olsen impact testers are engineered to meet the requirements of ISO 148, EN10045 -2, and ASTM E23 standards. They are widely utilized for purposes such as material acceptance, research and development, .

What is Impact Testing? Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and .

Impact Tests with High-Speed Testing Machines. The HTM high-speed testing machine is of universal use in plastics testing. It covers a very high test speed and large force range, and .IMPACT TEST. 1 – Impact properties. The impact properties of polymers are directly related to the overall toughness of the material. Toughness is defined as the ability of the polymer to . What Does Impact Test Mean? An impact test is a technique for determining the behavior of material subjected to shock loading in: Bending; Tension; Torsion; This test is .The impact test is to study the safety and reliability of WAAM component when subjecting to external impact forces, and the measured impact absorption work determines the toughness .

Impact Testing. What is an impact test and which measurands and parameters are important to know? Find out more on our impact test Glossary page.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Practical Application. . The impact of the water on the vanes generates a torque on the wheel, causing it to rotate and to generate electricity. 3. Objective. . Observe and note the flow behavior during the test. Measure the flow rate, .

types of impact tests

impact test specimen size

ebp hardness tester

These are some recommendations to ensure a test is valid: Clearly Define the Construct: Begin by clearly defining what the test is intended to measure.; Expert Review: Have subject matter experts review the test items . Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive (screw thread) somewhere, with the force transmitted to a cross-head and thence via a gripping system to the sample and then to a base .

IMPACT TEST . 1 – Impact properties The impact properties of polymers are directly related to the overall toughness of the material. Toughness is . Some practical examples of that include traffic accidents, stone impact on frontal surfaces of automotive and railroad rolling stock, accidents involving motorcycles or bicycles helmets .Procedure. Step 1 – First, the aggregate sample sieve through 12.5mm sieve and collect it which is retained in 10 mm sieve. Step 2 – Now, the sample should be dried through the oven up to 4 hours at 100 deg to 110 deg. Step 3 – Then, the aggregate sample should be filled in the metal cup by 3 layers. Each layer should be tamped 25 times by the tamping rod.The practical guidelines that have evolved, along with some practical examples of what happens when the guidelines are not followed, are documents, particularly with respect to overload detection and related errors. Impact testing first came into common use over 40 years ago, once the fast Fourier transform (FFT) was commercially available.

The impact test is a method for evaluating the toughness, impact strength and notch sensitivity of engineering materials. Engineers test the ability of a material to withstand impact to predict its behavior under actual conditions. Many materials fail suddenly under impact, at flaws/cracks or notches. The most common impact tests use a swinging .impact test, Test of the ability of a material to withstand impact, used by engineers to predict its behaviour under actual conditions.Many materials fail suddenly under impact, at flaws, cracks, or notches.The most common impact tests use a swinging pendulum to strike a notched bar; heights before and after impact are used to compute the energy required to fracture the bar .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Charpy impact testing determines the impact energy of materials.Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be . The test had a significant adverse impact on women – prior to the use of the test, 46% of hires were women; after use of the test, only 15% of hires were women. Dial defended the test by noting that it looked like the job and use of the test had resulted in fewer injuries to hired workers. The EEOC established through expert testimony .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .Procedure of Aggregate Impact Test The test sample consists of aggregates sized 10.0 mm 12.5 mm. Aggregates may be dried by heating at 100-110° C for a period of 4 hours and cooled. (i) Sieve the material through 12.5 mm and 10.0mm IS sieves. The aggregates passing through 12.5mm sieve and retained on 10.0mm sieve comprises the test material.

In nonsymmetrical members or structures, a resonant mode has a preferred direction of motion. Impact testing should be approached on an experimental basis by trying variations of impact velocity, direction, etc. Numerous frequencies may occur that make the mode shapes difficult to identify. Generally, the lower modes of vibration will be predominate.

However, it is necessary to calculate expected impact forces before measurement to know the approximate measuring range to be selected. The impact force can be calculated using different variables, for example change of velocity, breaking distance or impact time. Please refer to our impact force calculator made for practical use.Question: Strength of materials : Impact Test Experiment. I want a report about Impact test Including introduction, Explanation of the practical experiment method, conclusion. And if you have any additions or information that you can add about this experiment , you can add it.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . This article presents a test development project for classroom speaking assessment. With the aim of enhancing and specifically easing the process of test preparation and administration and .

With the advent of the 5G era, due to the innovation of 5G architecture, open source is widely used under the software-defined everything architecture, software security is even more important. According to National Institute of Standards and Technology (NIST) Special Publication (SP) 800- 64 Vol2 (Security Considerations in the System Development Life Cycle; SSDLC), .

Macro-Hardness (Rockwell and Brinell) testing is the most commonly applied materials test in industry due to several factors: 1) Macro-Hardness Testing is simple to perform and does not require highly skilled operators; 2) Through the use of different loads and indenters, hardness testing can be used for determining theYou have a very large sample size. As the sample size increases, the hypothesis test gains greater statistical power to detect small effects. With a large enough sample size, the hypothesis test can detect an effect that is so minuscule that it is meaningless in a practical sense. Virtual reality (VR) has emerged as a promising tool for enhancing practical skills of students in science and engineering education. However, the effectiveness of VR in this context remains unclear due to inconsistent findings across studies. This meta-analysis aimed to synthesize the existing literature and investigate the overall impact of VR on practical skills .

ebx300 portable hardness tester

impact test on metal specimen

WEB18 de dez. de 2023 · La Salle des profs. Le Dernier Jaguar est un film réalisé par Gilles de Maistre avec Lumi Pollack, Emily Bett Rickards. .

practical use of impact test|types of impact tests